Airbus Defence and Space, a subsidiary of the aerospace corporation Airbus Group that builds the Ariane 5 launchers for ESA and Arianespace, has presented the project of the Adeline (ADvanced Expendable Launcher with INnovative engine Economy) system to reuse part of rockets’ first stage. It also presented plans to build space tugs to be placed in orbit, where they’ll deliver newly launched satellites into their required orbit.

In recent years, many projects are being developed to reuse the more expensive parts of a carrier rocket, starting from their first stage. SpaceX is already testing the landing system of the first stage of its Falcon 9 rocket and, although it hasn’t yet succeeded, it’s making progress. ULA (United Launch Alliance) presented less than two months ago the project of its new rocket Vulcan, which provides a system to reuse its first stage’s engines.

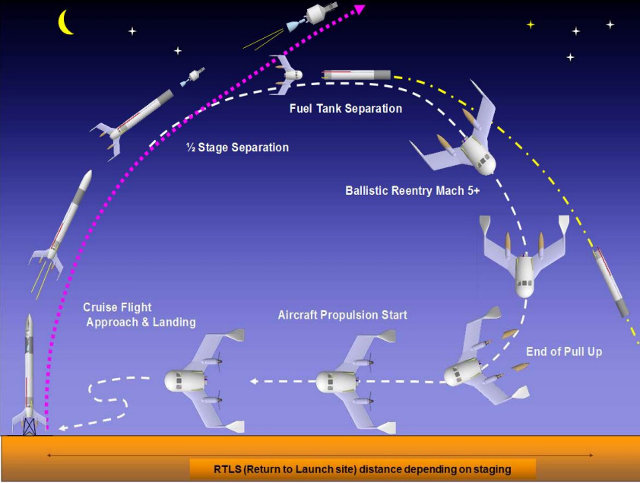

Each company is developing a different technology to recover the first stage of a rocket or at least its engines. The Adeline system is based on the idea of turning the most important and expensive part of the rocket’s first stage, its engines and electronic systems, into a drone after it completed its task in the launch.

Using a system of wings and a heat shield, the Adeline system could land alone but, unlike SpaceX project, it will land like a normal drone or an airplane, on a common airport runway. In this way, complex problems will be avoided such as that of landing vertically, as in the SpaceX project, or to require other support vehicles, such as in the ULA’s project.

Airbus has already carried out several tests with models as a proof-of-concept test of the Adeline system and they were successful. However, those were small models of a size smaller than that of a man. According to the company, the maiden flight of a true module could happen in 2025.

Another idea is to use orbiting space tugs for the last phase of the satellite launch. Today to put a satellite into its required orbit multi-stage rockets are used and the last part of the journey can be time consuming if you have to reach geostationary orbit.

A space tug could be put in orbit once and at that point the satellites could be launched only into a low orbit. There, the satellite would be captured by the tug to be carried into its required orbit. If this will allow a sufficient number of launches with smaller rockets, that will save money.

It will take years before we can see the various reuse systems in action but the fact that the biggest rocket manufacturers are working on the proves their importance. The ones that will make them work will be able to offer launches at much lower prices and launches cost many millions!

[ad name=”AmazonDocumentary”]

Permalink

I like this, great concept, love the drone reuse, but wont wings & engines add weight to drone segment & then to have landerlegs for booster sections alone.

Super idea.

Love to see Space X get onboard & SNC too.

Test in So CA & FL

Permalink

Certainly the landing system will add some weight, which also means some extra fuel. They’ll need to be able to reuse it for some flight for it to allow some savings.